Airborne/Structure Borne Ultrasound Inspection

Hindsight Infrared Services airborne ultrasonic inspection is a predictive maintenance tool that can help with the identification and location of electrical anomalies that possibly would have gone undetected with conventional methods. Ultrasonic inspection is a great add on to our successful infrared thermography inspection services.

How Airborne Ultrasonic Works: various electrical conditions emit sound waves that are not detectable to the human ear. Ultrasonic waves detectable by our sensitive equipment provides evidence of the existence of various electrical problems.

Corona, electrical arcing and electrical tracking can be located.

Ultrasonic Leak Detection

Zero business interruption. Designed to save money, fast. Guaranteed Payback!

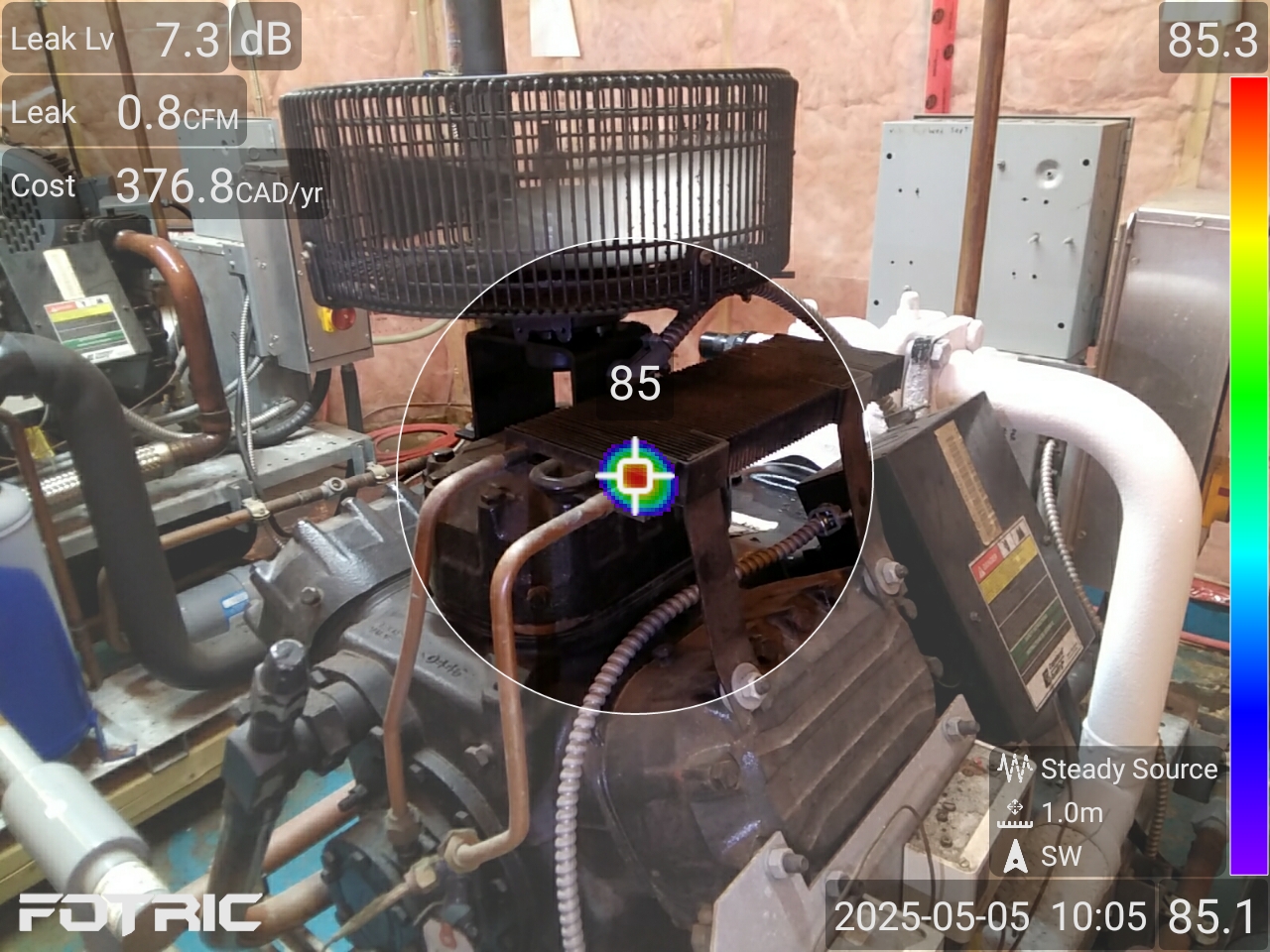

Our non-intrusive service identifies compressed air and gas system leaks. A combined leakage area of only 1/8 of an inch will waste thousands in costs over a year. Our ultrasonic service detects even the smallest leaks. Ultrasonic leak detection is completed during normal operating conditions. No shutdowns or production interruptions required. All leaks are tagged, documented and a complete report is included. Each report includes an estimate of how much the total of all leaks is costing your company.

Corona Detection

Locate damaging and dangerous high voltage corona, tracking and arcing detection service is available with Infrared Inspection, to form a complete picture of your electrical systems health.

Corona Discharge: Occurs when air molecules around conductors become electrically charged or “ionized”. Loss of energy, deterioration and failure of insulators result.

Voltage tracking and arcing in electrical supply systems is often hard to locate until it is too late. Let us find and monitor these conditions on your system.

Hindsight Infrared Services Inc. inspection can utilize both infrared thermography and ultrasonic detection techniques to locate problems on low voltage and high voltage distribution systems. Hindsight’s inspection process pinpoints unwanted conditions before negative results occur.

Hindsight Infrared Services inspects: Electrical distribution systems, transformers, breakers-all types, high voltage transmission lines, switchgear, underground vaults, circuit breakers, bus bars and risers, relays, contactors, electronic devices.

When metal clad enclosures cannot be opened, airborne ultrasonic inspection listens through the enclosure openings and vents.

Airborne Ultrasonic Inspection, when combined with our thermographic inspection, provides a complete picture on the safety and health of your equipment.

Predictive Maintenance

Hindsight Infrared Services combine ultrasound and infrared thermography to provide the ultimate maintenance inspection service. Our inspection service will save money and provide confidence in the safety and functional ability of the inspected equipment.

- Electrical arcing, tracking and corona detection.

- Bearings, brushes, gears, valves, steam traps.

- Pressure and vacuum leak detection, tanks, pipes.

- Exhaust system leaks, heat exchanges, boilers and condensers.

- Lubrication programs, ultrasonic monitoring